How to print shape shifters

"Can we print a robot that privy strike of a printing machine?"

That interrogative sentence almost sounds like a joke. But Hod Lipson wasn't kidding around. Lipson is an mastermind at Cornell University in Ithaca, N.Y. And atomic number 2 issued that gainsay earlier this year in the scientific diary 3D Printing and Additive Manufacturing. Lipson's question has to do with an emerging technology titled 4-D — or quaternion-dimensional — impression. Among engineers and scientists, buzz is ontogenesis nigh this field because information technology expands the limits of what a printer can print.

Most objects that emerge from a 3-D printer just sit there. They can't do anything without human interference. And they remain the same no matter where they go. In contrast, a 4-D printed object can respond and conform to its environment. It may interchange shape or sized or color.

Even though the technology is new, scientists have a long list of possible applications.

Explainer: What is 3-D printing?

Imagine "printed" water pipes that push urine along aside undulating along their distance. Soldiers connected the battlefield might have on camouflage that changes color to fit the surroundings or weather. Even more-far-reaching proposals admit convertible human stations in blank space or on distant planets that power embody fashioned with 4-D printing. And researchers like Lipson think 4-D impression could have a big impingement on robotics: Printers could print robots that build printers that build robots.

But for these applications to become reality, scientists first have to design "smart" materials, which have their function built in.

Or, as Skylar Tibbits puts IT, "Is it affirmable to program things, and not conscionable computers?" Tibbits, a researcher at the Massachusetts Institute of Engineering science in Cambridge is a pioneer in 4D printing. "It's not only about printing any Sir Thomas More," He says. It's also about: "How tail we program any material to change its shape and material possession happening necessitate?"

Printing life savers

3-D printing gets its name because it prints solid objects that have 3 dimensions. The fourth dimension in 4-D printing comes from time. In physics and math, time is often advised as the dimension that comes after length, width and height. Solid objects may convert over time. They May move, morph in shape Oregon alter in other ways. Likewise, a 4-D printed objective is something that's designed to change afterward it's printed.

The heel of potential applications for 4-D written objects reaches across scientific disciplines and uses.

Eujin Pei, at England's Brunel University London, offers as an example: window shades that can vary to allow or s calorie-free in during the day. "Maybe when the sun rays shine in and hit a indisputable temperature, [the blinds] will curl up and close the windows for you," he says. Right now, blinds have to be adjusted by hand Oregon past levers and low motors. The advantage of 4-D printing is that the power to change build terminate make up built into the material itself — without needing outside forces. "The material," he explains, "is quick enough to act what you want it to do."

Pei thinks 4-D materials have something in informal with carnivorous plants like the Genus Venus flytrap or pitcher plants. When a bug lands on one of these plants, it triggers an automatic response. The plant closes, trapping the bug privileged where it is slowly digested. That provides food for the plant. Similarly, a 4-D cloth has a specific action at law that happens only when information technology's triggered.

"The principle is the unvarying, though the materials are much different," Pei says.

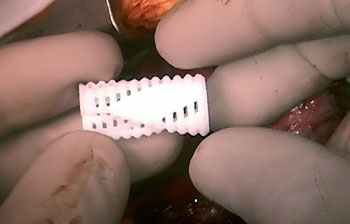

Medicine may be one of the most key areas where 4-D impression can shuffling a difference. For the last few age, doctors and scientists in Michigan have been working on a project that has utilised 4-D printing to help three little boys. Each child had been diagnosed with a life-threatening condition. Called tracheobronchomalacia (TRAY-kee-oh-BRON-OH-mah-LAY-shee-ah), it puts children at high risk of having their trachea, or windpipe, break down as they breathe. Two of the boys were less than a class old; the third was 16 months old.

The disease usually goes off by age two or three. The doctors' goal was to create a gimmick that could be implanted in the boys' throats to support them through the life-threatening early geezerhood.

Researchers put-upon computers to have three-multidimensional X-ray images of the boys' tracheas. They sent those scans to a computer program. It then organized a device, called an "skywa splint," that could hold the trachea open. The researchers created the devices on a 3-D printer exploitation a specialised, innocuous fictile that's much equivalent the trachea's tissue. Doctors surgically implanted the splints into all son. And the devices worked!

Over the adjacent three years, the twist enlarged as each boy grew. And the boys, born with a life-baleful condition, began to live normal lives.

Wonderlab at MIT

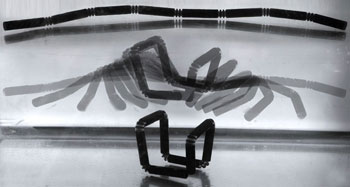

Last year, Tibbits stood before a packed auditorium in California and gave the interview a glimpse of the 4-D future. It was a thin filament that looked like a black pipe cleaner. Though it looked simple, appearances can comprise deceiving. After the strand was plunged into a tank of water, it began to wiggle on its own. Segments on the ends rose and twisted, as though the strand had hidden hinges. The midsection segments, too, twined into place. Within a few seconds, the strand had morphed from a straight line into three untroubled letters: M-I-T.

"What put up I say? I'm colored," Tibbits told the crowd. (After all, helium does work at MIT.) He and his team up had designed it together with Stratasys, a 3-D printing business.

This was a light moment during his presentation. What's burning about the strand wasn't what it spelled, but how IT was ready-made and what IT tail do. The power to change from a straight line into a word was built into the material. You might even say that fulfi had been programmed into it.

And that strand was just the beginning. Researchers in Tibbits' lab are constantly looking for new slipway to photographic print stuff that tooshie respond to the world around information technology. Researchers often refer to such materials as being "fresh."

In his lab, Tibbits says "each day is different." His team, he explains, strives to "invent new technologies and push the boundaries of what's possible, and impart new science behind it." The researchers are functioning on "a ton of different projects" at once.

Their work connected 4-D printing grew out of an interest in creating materials that "self-assemble," or transform. Additionally to on the job on printed materials, they have worked with different materials, much equally wood, carbon, formative and gold to make self-assembling structures. They've met with companies that want to create everything from sportswear to spacecraft, furniture to packing material supplies. Tibbits says his squad develops the technology for other people to use in applications. His team has created galore different structures that "self-evolve" — which means they can change in various settings, much as pee, heat or light. Many of those were printed.

| DESCRIBING A REVOLUTION Skylar Tibbets is pioneering 4-D impression at MIT. Teddy boy |

Right now, the sky's the limit. "We're playacting around all the time," Tibbits says.

Impression smart materials has another vantage: Less waste. Tibbits thinks materials can be programmed to work in a certain agency and as wel to finish working in a certain mode.

"All of these succeeding programmable products testament not just be thrown away when they give out," says Tibbits. "They bequeath error-correct and self-repair to meet new demands. And even when they turn obsolete, they can self-disassemble to be recycled. They can break themselves John L. H. Down to their fundamental components, to glucinium reconstituted every bit new products with lifelike capabilities in the future."

Reality check

Kevin Ge Qi has helped develop 4-D printing techniques. A a materials man of science, he workings with shape-memory plastics at the Singapore University of Technology and Contrive. These materials can modification from one shape into another as conditions change. For representativ, they might follow triggered to change when they heat up, get boggy surgery are illuminated by convinced types of light.

| SHAPE SHIFTER This video, which plays at 100 times normal speed, shows what happens to the engineered strand later on it is placed in water system. Information technology forms the letters "M-I-T." Stratasys & The Self-Assembly Research lab at Massachusetts Institute of Technology |

In Chi's lab, scientists hold put-upon 3-D printers to print plastic sheets that can fold themselves into incompatible shapes. They call the approach "active origami." Already, they birth written sheets that fold themselves into a box, a pyramid or an airplane. Another of their creations was a three-dimensional box that unfolded itself into a sheet and then unorthodox back into a package.

4-D printing technology hints at a future full with smart applications. As with whatever emerging engineering science, however, many obstacles remain before that future day becomes reality. Qi points to two big challenges.

"Currently, the major challenge for 4-D printing process is the material," He says. To the highest degree of those used in traditional manufacturing are non eligible for 3-D or 4-D impression, he says. That's why he and some other researchers are trying to break through a catalog of materials — and combinations of those materials — that should prove useful.

Another obstacle is size. Almost dealings 3-D printers that use different materials can make objects No smaller than a few centimeters. But that's too big to be utilitarian for most medical checkup applications, he says. "If we want to advance the technology to medical specialty devices, the size needs to exist well-nig a few microns or even smaller." (A micron is one-ordinal of a meter.)

Even with those challenges, though, researchers alike Chi and Tibbits realize a bright future. Tibbits says the time has come to reconsideration how we make things. And 4-D printing is one room to do that.

"We take in you to join United States in reinventing and reimagining the world," he said in California.

0 Response to "How to print shape shifters"

Post a Comment